Color Software

X-Rite color software helps you specify, formulate, and control color at all stages of the workflow. X-Rite software assures the accuracy and consistency of your color and offers the ability to analyze, store, and communicate results with your industry partners.

Autura™ Cloud-Native Software Solutions

Discover Autura, our innovative cloud-native software platform designed to revolutionize color formulation, matching, and quality control. Constantly evolving to meet your needs.

MeasureColor Software

MeasureColor is a color quality control software platform that helps converters and printers achieve accurate, consistent color with real-time feedback and robust reporting.

ColorCert Suite

The ColorCert Suite provides real-time color and print quality process control and reporting with 3 modules: process control, cloud-based color asset management, and ScoreCard Server.

Color iMatch Formulation Software

For Formulating Plastics, Coatings and Textiles

With Color iMatch formulation and quality control software, color matchers can accelerate color development through better first match performance and fewer correction steps.

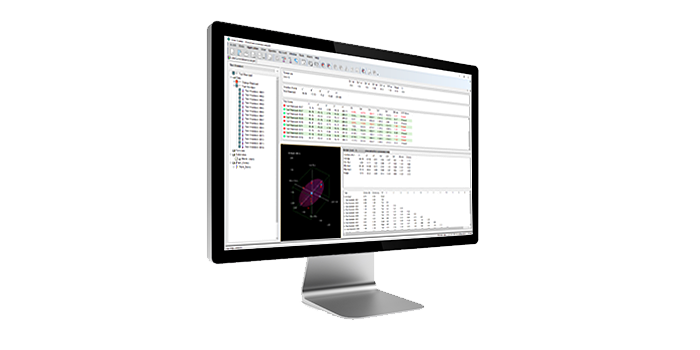

Color iQC Software

For Quality Control and Quality Assurance

With Color iQC software, specifiers and suppliers achieve consistent color throughout the entire supply chain in a variety of industrial, print, and packaging workflows.

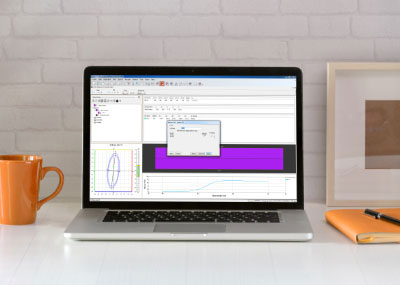

InkFormulation Software

For Formulating Inks

InkFormulation Software is a fast, accurate, consistent ink formulation, formula creation, storage, approval and retrieval solution for offset, flexo, gravure and screen-printing inks.

ColorDesigner PLUS Paint Matching Software

For Formulating Retail Paint at Point-of-Sale

Empower your color matching expertise with ColorDesigner PLUS, customer- and retailer-friendly software that delivers expert results through a flexible, tailored, adaptable workflow.

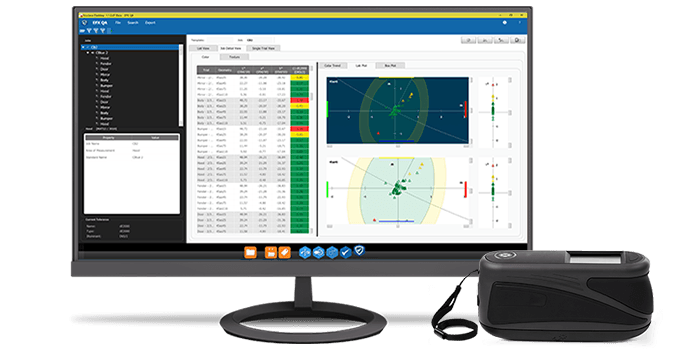

EFX QC Software

For Quality Control of Effect Finishes

Capture, define, and control effect finishes with digital data to enable real-time performance monitoring across an integrated supply chain with EFX QC software.

ESWin QC Software

For Inline Color Quality Control

ESWin QC connects with X-Rite inline spectrophotometers to monitor color directly on the production machine. It is used as a stand alone software or can comunicate with host systems.

ESWIN CLCC Software

For Inline Closed Loop Color Quality Control

ESWin CLCC connects with X-Rite inline spectrophotometers to monitor color and make adjustments for up to 3 colorants, plus OBA agents, for automated closed loop color control.

Color Formulation Software

An X-Rite formulation software solution provides ink, dye, and colorant formulators in a variety of industries the ability to create color recipes and manage inventories. When paired with a color measurement device, color formulation software can also help determine whether color correction is necessary.

X-Rite Color Formulation Software:

- Color iMatch: With Color iMatch formulation and quality control software, color matchers can accelerate color development through better first match performance and support color correction in fewer steps for plastics, coatings, and textiles.

- Autura Ink Software: A cloud-native ink formulation and quality control solution designed for ink manufacturers and suppliers. This integrated platform provides a secure and centralized solution for all formulation, storage, approval, retrieval, and QC needs.

Color Quality Control and Quality Assurance Software

Quality control is an integral part of the color quality process because it helps stakeholders work with confidence and ensure design intent is carried through to the final product, even across multiple locations. Implementing quality control software offers the ability to monitor and evaluate color workflows for precision.

X-Rite software can help your organization move from color quality control to color quality assurance with the ability to analyze why color errors occurred and what adjustments must be made to get color right. X-Rite quality control and quality assurance software can also maintain a complete audit trail to communicate color across the supply chain, prove compliance, and shorten time to market.

X-Rite QC and QA Software:

- Color iQC: With Color iQC software, specifiers and suppliers achieve consistent color throughout the entire supply chain in a variety of industrial, print, and packaging workflows.

- EFX QC: Capture, define, and control color and effect finishes like automotive paint and cosmetics with digital data to enable real-time color performance monitoring across an integrated supply chain with EFX QC software.

- ColorCert Suite: Today's packaging workflows are complex. The ColorCert Suite of quality control and quality assurance software simplifies color communication across all internal and external stakeholders. From prepress and the inkroom to production process control, ColorCert helps you control precise color and print specifications, uniting traditional silos of information into one common workflow. Modules include:

- ColorCert QA: ColorCert QA is a pressroom and ink room quality assurance solution that provides actionable guidance to manage color standards, improving color performance, and reducing make-ready time and waste.

- ColorCert Desktop Tools: ColorCert Desktop Tools is a modular solution to create accurate color specifications and control processes at multiple points throughout the packaging workflow.

- ColorCert ScoreCard Server: The ColorCert ScoreCard Server is a cloud-based portal that provides an overall view of print color quality, summarizes quality levels, and consolidates metrics filtered by a variety of criteria.

- ESWin QC: ESWin QC quality control software connects with X-Rite inline spectrophotometers to monitor color directly on the production machine. It can be used as a stand alone software or communicate with host systems.

- ESWin CLCC: ESWin CLCC quality control software connects with X-Rite inline spectrophotometers to monitor color and make adjustments for up to 3 colorants, plus OBA agents, for automated closed loop color control.

Device Performance Software and Dashboards

Device Performance Software and Dashboards give brands, suppliers, and manufacturers the ability to define color expectations and ensure correct color measurement practices, regardless of location or software configuration.

X-Rite Device Performance Software and Dashboards:

- NetProfiler: A blend of cloud database, client software and calibrated color standards that makes it easy to validate and optimize instrument performance, identify instruments in need of service, and reduce variation between devices.

- X-Rite Link: Enables your organization to monitor, maintain visibility, and gain real-time insights into your fleet of X-Rite color measurement devices from one convenient online dashboard.

Color Matching Software

In the retail paint industry, customers interested in creating a custom paint match often bring an inspiration item to the counter, for example, a pillow, toy, or paint chip. With a color measurement tool and paint color matching software program, paint counter employees can define custom paint colors and create a perfect paint match.

X-Rite Color Matching Software:

- ColorDesigner PLUS: ColorDesigner PLUS color matching software is customer- and retailer-friendly, producing expert results in a flexible, adaptable workflow that can be configured for individual needs.

Color Calibration & Profiling Software

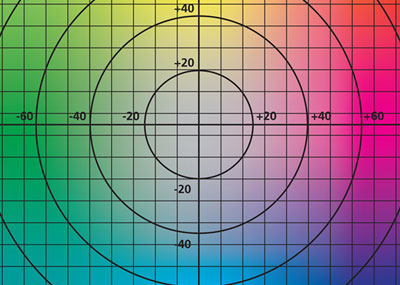

Not all color input and output devices are compatible. For example, input devices and displays use the RBG color model to capture color, while printers use CMYK to reproduce it. Saturation, hue, and color results can even vary between two display or printer models from the same manufacturer.

A color calibration program helps designers, photographers, and others who do color critical work make accurate editing and color correction decisions in color workflows. This tool can convert the language of each device to reproduce accurate color images.

X-Rite Calibration & Profiling Software:

- iProfiler: i1Profiler software delivers the perfect balance of color calibration automation with a full range of profiling options to achieve creative color control for monitors and printers. (H2)

Support and Contact

To learn which software is best for your color workflow or to get product help, our Color Experts are here to support you. Contact us on our website.

A color tolerance can ensure consistency and minimize variability. This whitepaper offers tips to select the right color tolerancing method and set a realistic color tolerance.

In this whitepaper, you will discover new tools and techniques for implementing a digitally-enabled workflow, including 4 keys that you won’t want to miss.

Working remotely? Learn how to digitize your color standards and share color data virtually so you can keep production moving.