Control Color Throughout the Production Line of Paper Mills

According to a 2019 Resource Information Systems (RISI) report, the paper market has a potential growth rate of 3.6% globally. In order to stay competitive and capitalize on this growth, pulp and paper-making companies need to build significant muscle to better position themselves to adjust to this increase in demand. It will be imperative that they are agile, innovative and responsive to changing customer demands to minimize business costs, reduce waste, and maintain customers.

X-Rite color measurement solutions can span the entire process – including inspection of incoming raw materials, color measurement of the pulp before the paper is produced, in-line measurement between the press and dryer sections with a good correlation to the laboratory for laminated paper, and finally before reel-up for automatic closed loop quality control – to keep color and brightness in harmony across the entire production line.

Customizable solutions from X-Rite Pantone provide paper mills the ability to:

- Maintain 100% control during production

- Reduce start-up time by up to 30% with start-up automation

- Shorten transition times by up to 50% with automatic color transitions

- Ensure reliable color measurement with <0.5 dE color correlation to the laboratory

- Reduce wasted dyes or optical brightener agents by up to 10%

- Lower maintenance costs

Trust X-Rite Pantone to ensure a quick and accurate inspection of pulp and throughout the line.

How We Help You Ensure Color Control

Color Inspection for Laboratory: Inspecting color of incoming materials before pulp preparation begins, and while mixing is critical to keeping business running efficiently. X-Rite solutions help laboratory professionals quickly identify color inconsistencies.

- ColorXRA 45Lab: A compact, fully functional 45:0 benchtop spectrophotometer with excellent spectral resolution of 1 nm and adjustable UV, ideal for color measurement in paper and textile laboratories.

- ES Win Quality Control: A customizable software solution that integrates with inline spectrophotometers to evaluate optical brightening agents and control color quality, evaluate trends, and correct current or emerging problems.

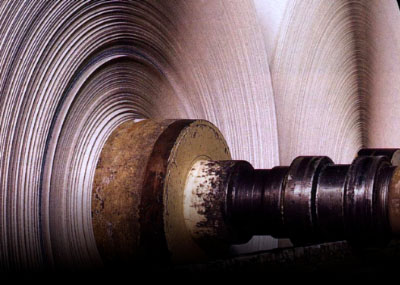

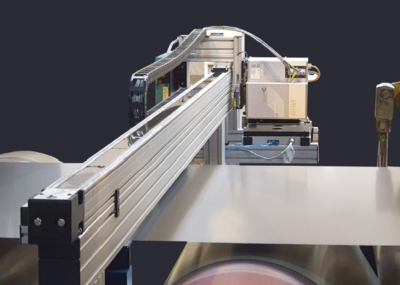

Inline Color Measurement for Production: Measuring and monitoring color on the production line is key to ensuring stable and accurate color on paper, minimizing cost and waste that can result in thousands of dollars in financial loss. X-Rite solutions provides operators the tools they need to avoid these costly line errors and rework.

- ColorXRA 45: This inline measurement spectrophotometer measures color, whiteness, and brightness and evaluates color deviation to enable corrections. With standardized 45°:0° measurement geometry, it provides good correlation to laboratory instruments.

- ESWIN Closed-Loop Color Control: When combined with an X-Rite inline color measurement instrument, ESWin Closed Loop Color Control manages color quality on continuous process production lines, displays results, and runs automatic in-line closed-loop color control on paper mill production lines. It goes from any start color to the target color in full automatic mode.

How Inline Color Measurement Works

LEIPA Paper Mill Testimonial: The Benefits of Inline Color Measurement

The LEIPA paper mill in Schrobenhausen, Germany produces colored envelopes, packaging papers, board, manila board, and other specialized papers. Learn how an inline solution from X-Rite that includes the ERX50 inline spectrophotometer and ESWin Closed Loop Color Control software has improved their color management and helped them become more competitive in a demanding market.

Featured Resources

An X-Rite inline solution can help paper mills evaluate color quality and make real time adjustments throughout production to keep color and brightness harmony.

Learn how inline closed loop color control solutions for paper deliver consistent results, enabling you to realize a quick ROI and improve overall production output and quality.

Learn how X-Rite’s inline color measurement solutions evaluate color consistency throughout production so immediate corrections can be made if color shifts.