As we close out 2016, it’s time to look ahead to 2017 and the upcoming manufacturing trends that will influence how we do business in the New Year. With rapidly changing technology, it’s difficult to know exactly what’s coming next, but we can definitely make some predictions.

Over the past year, I have interviewed many customers across a variety of manufacturing industries to learn more about their industry concerns, the design and manufacturing challenges they face, and the technologies that excite them. As I look into my crystal ball for 2017, here are some manufacturing and business trends to follow over the next 12-18 months.

Image courtesy of just-style.com.

On-shoring

Increased labor, transportation and energy costs coupled with stricter regulations and environmental concerns have lead many manufacturers to rethink offshore manufacturing strategies. While we are likely to see new government and trade policies that encourage local manufacturing, on-shoring has been a growing trend for the last three to four years. This is likely to accelerate as manufacturers adopt digital technologies that allow products to be designed once and produced locally.

The combination of standard operating procedures and integrated manufacturing systems to analyze performance and quality control will enable the adoption of local-to-local manufacturing across a range of consumer goods industries.

Transparency to the Supply Chain

Brands will continue to work towards a higher level of transparency in their supply chains, driven by the continuous pressure to reduce costs and innovate. Transparency is also a trend valued by many consumers, especially millennials. These consumers want to know where something is manufactured, what materials are used, and how long it takes.

Enterprise resource planning (ERP), management information systems (MIS) and product lifecycle management (PLM) systems are all evolving to provide more transparency and visibility into the supply chain process. Systems will be more connected, bringing supply chain data upstream where it can be analyzed. As a result, the product design to manufacturing process will become highly digitized. Brands that review hundreds or thousands of samples daily will be able to analyze them digitally, speeding up the entire processes and making more informed decisions when issues arises.

Custom Manufacturing

In 2017, we will see more custom manufacturing in textile and fashion. Short run custom manufacturing began with the photo market, and now extends to unique gift offerings. Advances in digital printing and 3D printing are creating new opportunities for short run and custom run printing. It will enable large and small brands to create unique “short run fashion,” which creates new opportunities for the apparel industry as well as the commercial printing industry.

Image courtesy of wired.co.uk.

Changing Face of Brick and Mortar Shopping

The Amazon Go announcement drastically rethinks the way people shop for groceries. It combines online and brick and mortar shopping using innovative technology to create a new shopping experience. More importantly, Amazon is recognizing that that the customer journey is both physical and digital. Rumors of 20-2,000 stores by 2018 have been surfacing.

In order to own the point of purchase for consumers, Amazon will need to partner with brands to expand this concept. Imagine a BestBuy partnership with a simplified show room that allows consumers the opportunity to touch and experience an appliance, then click to order it. Pop-up store partnerships would allow both Amazon and a brand to trial new markets and products while sharing the costs. Brick and mortar drives brand loyalty, and Amazon loyalty is built through their Prime service. Together, the two offer a unique way to both lower costs and drive customer engagement.

Image courtesy of theverge.com.

M&A Activity

We will see further consolidation of the fragmented plastics market. There are a number of smaller independent plastics companies that offer excellent opportunities for larger players to create inorganic growth through acquisitions. In addition, I see a lot of M&A opportunity across vertical markets, such as commercial printing and plastics used in packaging. Through mergers and acquisitions, companies will be able to expand their reach into a specific application. We have already started to see this happen with VisiPak’s acquisition of National Plastic, expanding the shapes and sizes of thermoform packaging, and Nanogate’s purchase of Jay Plastics to expand their high-tech plastic and coatings. For companies where M&A many not be the right strategy, they can instead invest in new injection molding plants such as Nissei is in Texas.

Designing for 3D

In December, Adobe rolled out its new Felix Program which will simplify 3D design process. This announcement has a significant impact on the graphic design community and will allow graphic designers to expand their skill set and enter 3D. Graphic designers are the largest group of designers and they design for a slew of products. The software and ecosystem of Adobe Creative Cloud will make learning 3D easier, and integrating 3D with Adobe’s tools like Photoshop and their stock library will help to centralize the creative process.

Composite created in Project Felix. Image courtesy of blogs.adobe.com.

Solar Coating

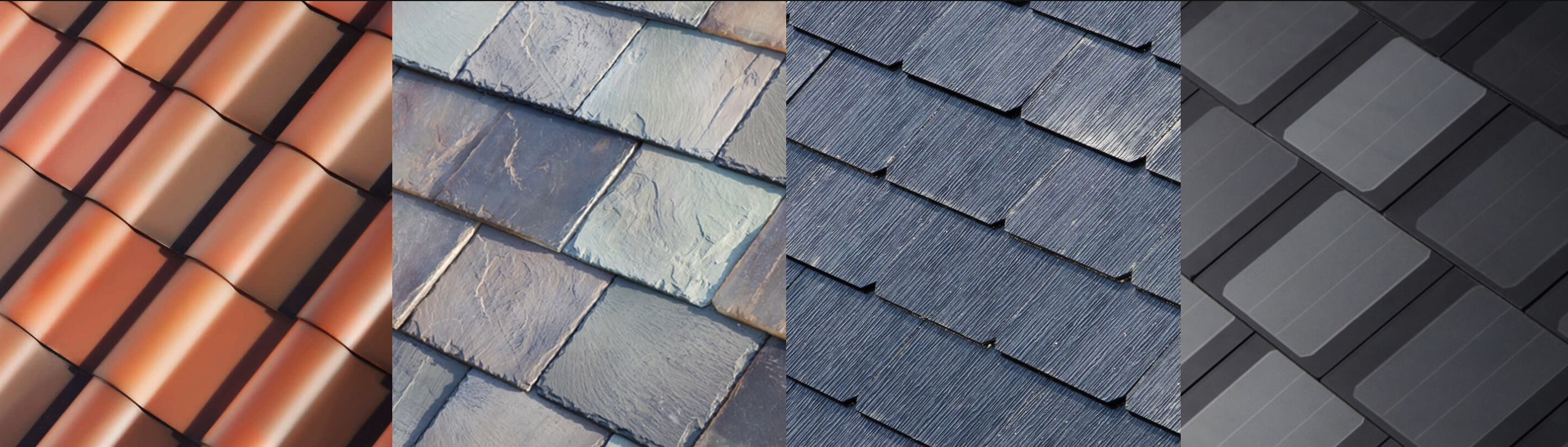

Solar coating technology will be commercialized to turn everyday objects into energy sources. Over the next few years, this technology will mature and be used on windows, roof tiles, phones and cars. Companies to watch include NanoFlex’s Photovoltaic coating for automotive, and Tesla’s recently unveiled solar tiles for homes. Since they look like regular roof tiles, the investment is visually appealing for homeowners who did not like the look of larger mirror mountings.

Image courtesy of tesla.com.

Stay Tuned!

Only time will tell if these prediction and trends come true, but it will be interesting to see how they evolve over the next few years. In our next post, Ray Cheydleur, X-Rite Portfolio Manager for Printing and Imaging Products will make his prediction for the packaging and printing industries.