Create a Foundation to Stay Ahead of the Curve with Color Accurate Creams, Liquids, and Lotions

Cosmetics that have a cream, liquid, and lotion base come in a variety of colors and textures. These cosmetics are expected to consistently deliver exact color as consumers purchase these products with the expectation that it will be the same each and every time. Delivering to these incredibly tight standards adds complexities in how manufacturers can control and seamlessly manage color. X-Rite offers the expertise and technologies to help cosmetic manufacturers measure, formulate, and control the quality of creams, liquids, and lotions throughout production.

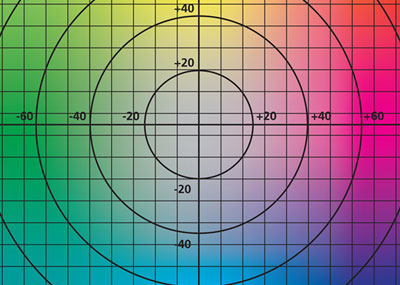

Successful cosmetic color quality control and formulation goes beyond vibrancy to include a variety of textures and shades. To accurately reflect the natural skin tone light needs to pass through and scatter in many directions on the skin. An accurate color solution is required to control these complexities and ensure the cosmetic color is correct from formulation to production to application.

With X-Rite solutions, cosmetic manufacturers of creams, liquids, and lotions can:

- Formulate precise colorant recipes to meet customer-provided standards.

- Deliver accurate color readings on both wet and dry cosmetic textures.

- Reduce human error and waste due to rejects and rework.

Quality Control for Cream, Liquid, & Lotion:

Controlling color quality throughout production enables manufacturers to deliver consistent color and product integrity every time. X-Rite tools take precise color measurements of all cosmetic textures, even liquids for an efficient production workflow.

- MetaVue VS3200 Non-Contact Benchtop Spectrophotometer: Measure wet and dry creams, liquids, and lotions against a standard with this non-contact benchtop to ensure a color quality audit trail.

- Color iQC Software: Align expectations and monitor color accuracy throughout production processes to provide an audit trail for continuous improvement.

Formulation for Cream, Liquid, & Lotion

Achieving the tightest tolerances while providing optimal initial color matches is imperative for cosmetic manufacturers. X-Rite tools ensure you can meet customer-provided standards and make formulation faster, easier, and more precise.

- Ci7860 Benchtop Spectrophotometer: Take precise color measurements for seamless communication of color-critical values and specifications on creams, liquids, and lotions.

- Color iMatch Software: Provide optimal initial color matches and reduce wasteful formulation attempts when formulating new cosmetic colors.

Featured Resources

Whether you manufacture cream, liquid or powder cosmetics, join X-Rite and Pantone to learn how to control cosmetic color from design to print to shelf.

A color tolerance can ensure consistency and minimize variability. This whitepaper offers tips to select the right color tolerancing method and set a realistic color tolerance.