Print Does Not Match Display

To have a print and display match in a color managed workflow, at a minimum, three components are required:

- An accurate monitor profile

- An accurate printer profile

- Software properly configured to use them

The monitor profile allows ICC-aware applications like Photoshop to accurately display your image's color. To achieve a similar appearance in print, the existing color information must be translated to the appropriate values for printer/paper/ink combination being used. In addition, the printer profile must accurately describe the appearance of ink on the page. "Canned" profiles from printer or paper manufacturers may not always accurately represent the behavior of your specific device. Correct implementation of your printer profile is a critical component in matching the screen and the print.

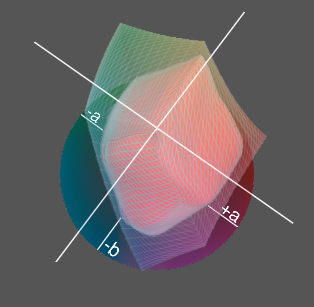

In the vast majority of situations, the display can reproduce a larger range of colors (gamut) than the printer can. Therefore, we cannot make the print look like the display, but instead, must make the display look like the print. The image below illustrates this issue.

The smaller red object represents the range of colors that a sample printer can reproduce. The larger translucent object represents the range of colors reproducible by a sample display.

Making the display look like the print requires that you send the image through the printer profile and back through the monitor profile. This is commonly referred to as "soft proofing. The softproof feature in certain third part software applications will allow you to simulate an output condition for best screen to print match.

If you are having difficulty getting a match from print to monitor, you will need to examine each of the items above. All three must be in place to achieve a reasonable match.

Note: A short video is also available on YouTube. Click here to open the video in a new browser window.