Ensuring color consistency in commercial printing and packaging is critical for maintaining brand integrity and meeting customer expectations. One of the most effective ways to achieve this is by leveraging quality control software that utilizes precise color tolerancing methods. In this blog, we will explore different tolerancing techniques and how QC software enhances accuracy in color control. The Challenge of Visual Color Assessment Many assume that visual inspection alone is sufficient for...

A recent amendment to the EU Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment will remove the current exemption for mercury to be used in a number of types of fluorescent lamps for special purposes by 24th of February 2025. These bulbs are defined under clause 2(b)(4)-I of the EU REACH directive. After the expiration date, the sale of new equipment including fluorescent technology under this exemption will not be allowed in Europe. Th...

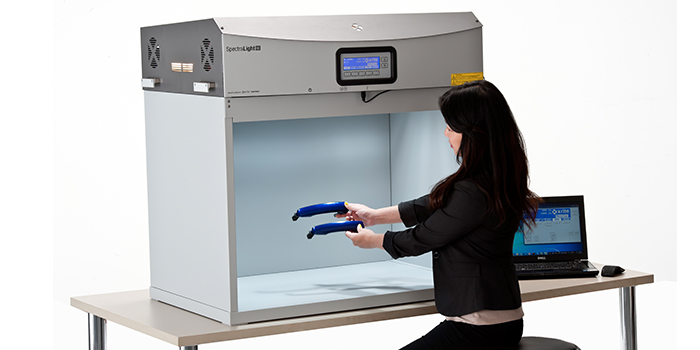

Does your quality control program include visual evaluation? If not, it should. Using the SpectraLight QC as part of a color evaluation workflow. No matter your industry, judging color is more than just measuring samples with a color measurement device. Just because a spectrophotometer says your color is within tolerance, doesn’t necessarily mean it will look right to the human eye. To minimize customer rejects, your color control process needs to include visual evaluation in a light boo...

Like you, digitization and sustainability are top of mind. However, colour is often overlooked when it comes to textile product development. Digitizing the textile supply chain and applying colour management at each stage will ultimately pay for itself through more accurate colour, faster production, and less waste. With over 60 years of innovation and proven expertise in colour management and colour measurement, X-Rite has solutions to support everyone in the textile industry, including appare...

As the temperature of light changes, so does our perception of color. As I mentioned in our last post, light plays a huge role in the way we perceive color. Today we’ll look at the science of color in manufacturing and photography; specifically how an object’s reflective and absorptive properties and viewing technology can impact the colors we perceive. To reflect or not to reflect… that is the question. The colors an object absorbs and reflects is determined by its material – is it metal, plas...

According to autolist.com, over 80% of cars produced today are white, black, or some shade of gray. It’s not necessarily because bright and bold colors are more difficult to produce and match than their grayscale counterparts, they just take longer to get through the inspiration and car design process. Believe it or not, producing a new auto color can take up to five years before it makes it to the showroom floor. It’s a long, tedious process for designers, paint...

Light booths provide a controlled environment for judging color under different lighting conditions. They can help visually evaluate how different types of light will affect the perception of color, evaluate the color of raw materials before and after production, and ensure different components will remain uniform once they’re assembled. But not all light booths are the same. With NIST traceability and ISO 17025 accreditation, X-Rite offers worldwide competence in calibration, cert...

The best way to visualize how color will react in real world lighting conditions is to use a quality light booth. Traditional light booths contain common illuminants like daylight, incandescent, and fluorescent to replicate how color will look in the retail store and post-purchase in outdoor and home lighting. Today, the increased use of LED lamps in home, commercial, and retail environments is impacting decades of standardized lighting procedures. How LED is Changing the Game LED li...

The Pantone Color of the Year announcement is always exciting. Not only does it set the stage for upcoming trends, it also provides brand owners and designers critical guidance for marketing and product development. However, those who are charged with manufacturing products and packaging with trending colors (like 2021's Ultimate Gray and Illuminating) know it doesn’t “just happen.” It takes time and effort to incorporate new colors. Whether you work in paints, plasti...

Black Friday. Not only is it the much anticipated start to holiday shopping, it’s also a day manufacturers have been preparing for all year long. Whether mass-producing holiday cards, candy canes, plastic toys, or festive clothing, accurate color is a must. Manufacturers can’t ship two of the same toy if they won’t match on the showroom floor, and holiday sweaters that are a shade off will end up at a discount store instead of a fashion boutique. Perfection is especially import...

As the industrial plastics market grows increasingly competitive and demands more sustainable practices, manufacturers need new ways to formulate and produce accurate color faster, with less waste. Digital color standards are one of the most effective tools to bridge this gap. They also enable color work and communication from remote locations. With digital color standards, brands and designers can set clear expectations with supply chains. In turn, suppliers can achieve color goals wit...

Whether you work with plastics, coatings or textiles, you must consistently achieve in-tolerance color or your product could be rejected before it even makes it to the shelf or showroom. This is especially true for brands that rely on off-site suppliers and manufacturers for raw materials and parts that come together at assembly, such as the plastic dashboard, fabric seats, and coated interior panels of a car. Even if each site produces in-tolerance color, it must be monitored an...

No matter the industry, our customers are all working toward the same goal: Achieve accurate color and keep production moving. Even in the best conditions, color data can be a challenge to capture and share. COVID-19-related travel bans and social distancing guidelines are making it harder than ever. Today we’ll share three easy ways to remotely share color data so you can achieve your color goals without shipping physical samples or making onsite visits. The Benefits of Digit...

Appearance is more than just color. It’s an all-inclusive look at everything inherent to an object, including texture, gloss, transparency, translucency, and special effects like sparkle and shimmer. When viewed from different angles or under different lighting conditions, appearance effects can change our perception of color. That's why it’s important to control both color and appearance throughout design and development. Durable goods brands use appearance effects to captur...

Managing color throughout production is always a challenge, but advances in color technology, like the metallic, shimmer, and pearlescence effects designed to capture consumer attention, are taking the frustration to a whole new level for quality control managers. This is especially true when producing parts that must match at assembly, such as the metal panels for a home appliance or the painted side mirrors for a vehicle. Special effects are tricky to control because our perception can c...

When choosing a food product, consumers demand consistency in both taste and appearance. While a lighter batch of oranges may still produce a delicious juice blend, a pale color can jeopardize USDA approval and leave consumers questioning the quality. Unfortunately for food and beverage manufacturers, the color of food – especially drinks like fruit juice and blended cocktails – is one of the most difficult things to control during production. Here’s why. 1. Liquid is hard to...

There’s been a lot of research around the role color plays in how we expect food to taste. The fact is, we judge flavor by the color of the food or drink, even before the first taste. We expect red foods to taste sweet like strawberries or cherries. White should taste like vanilla, and green is probably limey and tart or minty. Color cues can even determine whether we take that first bite. Most of us won’t even consider trying a food like mashed potatoes or pumpkin pie if it is ...

Controlling color on cylindrical-shaped items like cups, cans, and tubes is a challenge because it’s hard to properly align the measurement device with the sample. Many printers and manufacturers cut a piece from the finished product and lay it flat to take a measurement. While this method works, each sample takes time to cut, wastes product, and risks the safety of the employees who are cutting the samples. A Faster, Safer Solution X-Rite’s Cup and Cylinder Fixture works ...

Are you wasting too much time and money on incorrect color? Even if you use the best color measurement tools available, your color will still fail without quality control. Quality control (QC) means verifying the color you specify is the same color you manufacture, throughout production. Setting up a QC program can help you accurately communicate color with clients and suppliers, inspect raw materials before you begin working, and verify your color is correct before you ship. Five Impor...

Your customer rejected your latest shipment due to color. You checked the color before you sent it and it passed tolerance… You did everything the same way last time and it passed tolerance… So why did it get rejected now? We get this question from our customers all the time. The Dreaded “Error Stack” Color rejections create waste and increase production costs. Unfortunately, there are a lot of variables that contribute to the color you produce,...