Controlling Color Difference of Plastic Injection Molding Products

With pressure to reduce waste and speed up time to market coming from all angles, plastics molders must continuously evaluate processes to ensure they have the right set of solutions to keep the line moving. Comprehensive color solutions ensure incoming raw materials are on spec and plastic injection molding color stays in tolerance from color formulation throughout production. At X-Rite Pantone, we continue to innovate plastics solutions to ensure molders are profitable and meet on-time delivery. Our solutions can span the entire plastics injection molding process – from inspection of incoming raw materials, color matching in the laboratory, measuring the product during high injection speed production, and final inspection – to ensure the right color for a cost-effective product.

Customizable solutions from X-Rite Pantone provide plastic molders the ability to:

- Confirm color is within tolerance with highly accurate color measurement instrumentation

- Avoid color streaks and gloss difference

- Identify and correct common problems to achieve stable and consistent color matches

- Ensure all devices are measuring accurately and consistently across a global supply chain

- Minimize wasted raw material and rework due to inaccurate color

How X-Rite Pantone Can Help Ensure Color Accuracy for the Injection Molding Process

Raw Materials Color Inspection and Color Control Management for Molders:

Inspecting color of incoming raw materials and plastic colorants from color suppliers through coloring plastics and monitoring color on the production line is critical to keep your business running efficiently. X-Rite Pantone solutions help monitor color throughout production, evaluate color difference, and quickly identify factors that impact color inconsistencies to avoid costly rework.

- Ci64 Sphere Handheld Spectrophotometer: Carry this device anywhere to validate color quality and recognize color difference on shiny, glossy, or reflective materials.

- Ci7800 Sphere Benchtop Spectrophotometer: Ensure accurate and quick inspection of incoming raw pellets with reflectance and transmission modes and fixturing accessories to accommodate different sample sizes and shapes.

- NetProfiler: Verify all devices are calibrated, optimized, and delivering the same color data to reduce inconsistencies across devices and provide incoming material inspection confidence.

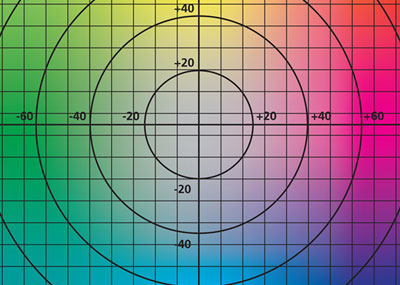

- Color iQC: Analyze color difference and identify why color errors occur so adjustments can be made to ensure all components meet color expectations.

Featured Resources

A color tolerance can ensure consistency and minimize variability. This whitepaper offers tips to select the right color tolerancing method and set a realistic color tolerance.

Should You be Using a Benchtop Spectrophotometer for Quality Control?