Inline Spectrophotometers

X-Rite’s inline spectrophotometers are mounted above continuous process manufacturing lines to measure color in real time, without stopping production. Real-time color information from an inline spectrophotometer enables production operators to make accurate color adjustments to increase color consistency and minimize costly production line errors.

Adding ESWin CLCC software can create a continuous monitoring system to catch color drift immediately and make color changes before production moves out of tolerance.

X-Rite's inline systems are turn-key, durable, and offer maximum instrument uptime for fast ROI, and correlate well with X-Rite laboratory spectrophotometers.

ColorXRA G3 Glass Reflectance Spectrophotometer

For Reflectance Measurement on Glass Coatings

The ColorXRA G3 non-contact reflectance spectrophotometer measures color quality on multi-silver layers on coated glass and other non-scattering samples in the lab and inline throughout production.

ColorXRA 45

For Inline Paper and Plastic Color Measurement

A compact UV-calibrated 45°:0° inline, non-contact spectrophotometer, ideal for identifying color shifts early and throughout production for paper and plastic applications.

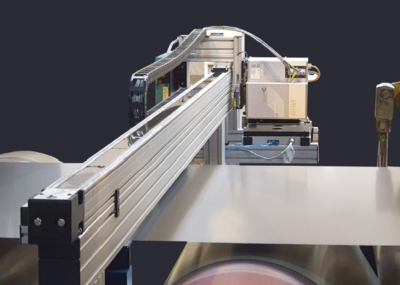

ERX145

For Inline Coil Coating Measurements

The ERX145 non-contact spectrophotometer is designed to capture color measurements on coil coatings in the lab and on the production line.

ERX130

For Inline Reflectance Measurements

The ERX130 inline spectrophotometer captures reflectance measurements on homogenious, small patterned and varigated samples during production to provide operators with real-time color information.

ColorXRA 45 Pulp

For Measuring Pulp Inline

The ColorXRA 45 Pulp is an inline spectrophotometer to measure color, whiteness and brightness during the pulp manufacturing process to identify shifts early so corrections can be made.

GlossFlash 6060 Glossmeter

For Inline Gloss Measurement

A non-contact, inline glossmeter to automatically measure gloss on the production line of coated surfaces like coil coating, grinded metal surfaces, anodized aluminum, plastic sheeting and tiles, and decorative façade elements.

Who Uses Inline Solutions?

X-Rite inline solutions can help you achieve color accuracy for all stages of manufacturing for paper, coil coating, plastics, coated glass, and textile industries. Learn more about inline color measurement for each industry, below.

Inline Solutions for Paper

To keep color and brightness constant throughout production, X-Rite’s inline paper color measurement systems span the entire process, from laboratory measurement to pulp, wet sheet, and measurement before reel up for all paper and board types, including infinite layer color, opacity and whiteness/brightness.

Inline Solutions for Coil Coating

An X-Rite inline solution for coil coating can move left to center to right to automatically measure color and gloss on a high-speed production machine. This system monitors temperature to correct thermochromaticity and offers excellent inter-instrument agreement with laboratory instruments.

Inline Solutions for Plastic Compounds

Instead of correlating pellet color deviation to the extruded plaque, an X-Rite inline spectrophotometer can measure above the separation sieve behind the granulator to detect issues earlier and reduce wasted batches.

Inline Solutions for Transparent Film

X-Rite’s inline transmission measurement system can help operators continuously monitor visual light transmission and haze and correct even slight changes immediately to avoid costly production line color errors.

Inline Solutions for Opaque Film

X-Rite’s inline reflectance measurement system, including ColorXRA 45 and ERX130 plus ESWin QC and ESWin CLCC can help operators continuously monitor color and correct even slight changes immediately to avoid costly production line color errors.

Inline Solutions for Glass

X-Rite’s inline glass color measurement system uses a non-contact spectrophotometer to measure non-scattering samples, like glass panes, directly on the production machine to measure and quantify glass and functional layers like low-E or solar protection.

Inline Solutions for Denim Yarn

An inline color control solution can monitor denim yarn at multiple times in the dye process, over the rollers on a traversing beam or on an inspection table for spot measurements, to evaluate color quality.

Inline Solutions for Carpet

X-Rite’s inline carpet measurement system can be used as a stand-alone unit or with a traversing beam for side-to-side monitoring to detect color deviations in machine and cross direction to evaluate the quality. Using this color data, runs can be qualified and sorted in different qualities to ensure a homogenous appearance within one shipment.

Inline Solutions for High Visibility Clothing

Because of the fluorescent colors, the physical illumination must be adjusted to CIE D65 not only in the visible range, but also in the UV area below 400 nm. By measuring UV included and excluded, the X-Rite spectrophotometer uses a built-in Xenon flash lamp to adjust to the CIE D65 standard to ensure color is within tolerance for the DIN EN20471 specification.

Learn how X-Rite’s inline color measurement solutions evaluate color consistency throughout production so immediate corrections can be made if color shifts.

Learn how X-Rite's inline solutions monitor and control the color of plastic film and sheets throughout production so corrections can be made early before the run is impacted.

Learn how inline closed loop color control solutions for paper deliver consistent results, enabling you to realize a quick ROI and improve overall production output and quality.