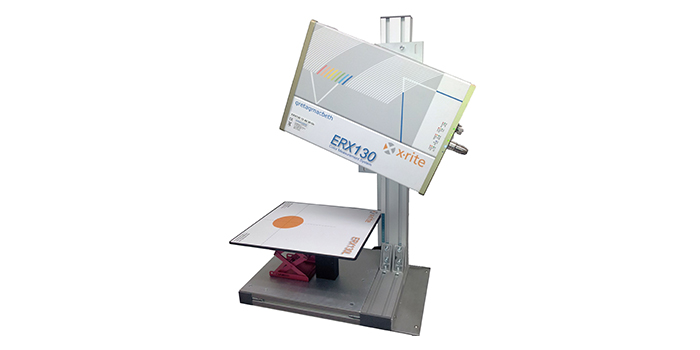

ERX130

For Inline Reflectance Measurements

- Takes reflectance measurements on the production line

- Connects with ESWin QC or CLCC to monitor color quality and make automatic adjustments

- Offers a 300mm measurement distance and 90mm measurement spot

Warns Operators of a Color Shift

Color shifts during production can result in costly waste, rework, and delayed time to market. Designed to take reflectance measurements on homogeneous, structured and small patterned samples, the ERX130 is an inline, non-contact spectrophotometer that meets the needs of a variety of industrial applications. When paired with ESWin CLCC software, it becomes an automated inline quality control system that performs color adjustments automatically.

Avoid Costly Production Line Errors

The ERX130 non-contact inline color measurement device takes reflectance measurements on the line throughout production. When paired with ESWin QC software, it provides actionable guidance so operators can make immediate corrections without stopping production. It is easy to operate and offers comparisons to specific standards or absolute measurements. By identifying a color shift before it's visible to the human eye, changes can be made before the batch is ruined.

Measure Color on Variegated and Small Patterned Samples

Featuring coaxial geometry, a wide measurement distance, and a large measurement spot, the ERX130 is ideal for monitoring color on a wide range of textured, finely patterned, and glossy industrial materials, including vinyl, textiles, pigments, paints, plasters, films and bulk goods like powders and sands.

ERX130

Specifications

| Measurement Geometry | coaxial to the illumination (= 45° to the gloss axes) |

| Measurement Time | flash |

| Measurement Working Distance | 300 mm |

| Short Term Repeatability - White | dL*, da*, db* < 0.03 |

| Spectral Interval | 1nm |

| Spectral Range | 330-730 |

Support

Resources