Ensure Product Quality with Color Measurement Solutions for Industrial Paint & Coatings

Industrial paint and coatings come in a variety of colors, textures, and effects to enhance the look.

Our products manage color for:

- Industrial Coatings

- Powder Coatings

- Coil Coatings

- Adhesives and Sealants

- Wood Preservatives & Coatings

- Aerospace Coatings

- Marine Coatings & Gel Coats

For industrial paint and coatings, color impacts more than just aesthetics. X-Rite’s color measurement solutions can help you achieve accurate and consistent color, time after time.

- Deliver initial color matches with an average delta E that is half that of our competitors

- Confirm color is within tolerance with highly-accurate color measurement instrumentation

- Identify and correct variances early-on to minimize waste and rework

- Maintain 100% control on your moving production line with inline color measurement systems that measure color and gloss without contact

- Ensure all devices are measuring accurately and consistently across a global supply chain

Quality Control for Industrial Paints & Coatings:

A dependable quality control program streamlines approval processes and reduces color inconsistencies. X-Rite’s quality control solutions are the tools you need to communicate, control, and evaluate color.

-

Ci64 Sphere Handheld Spectrophotometer: Carry this device anywhere to ensure color quality on shiny, glossy and reflective coated surfaces.

-

MA-5 QC Multi-Angle Spectrophotometer: Evaluate special effect paint and coatings and identify color defects early in the process to avoid unnecessary rework.

-

MetaVue VS3200 Non-Contact Benchtop: Take accurate color measurements on liquid coatings without contaminating the instrument or sample.

Formulation for Industrial Paint & Coatings:

Reacting quickly to trends with new color palettes requires a dependable formulation program. X-Rite’s color formulation solutions reduce the steps to an acceptable color match, manage recipes and specifications, and provide consistent color reproduction.

-

Ci7800 Benchtop Spectrophotometer: Ensure a precise measurement using the on-board camera for preview and active targeting.

-

Color iMatch Software: Maximize formulation efficiency to better characterize colorants and guarantee match prediction confidence.

Inline Color Measurement for Coil Coatings:

Maintaining on-spec color throughout production requires an inline closed-loop color control solution that monitors color and gloss on the production line and through final QC. X-Rite’s comprehensive solution ensures faster start-up with streamlined production and provides the data necessary to track production quality and results.

-

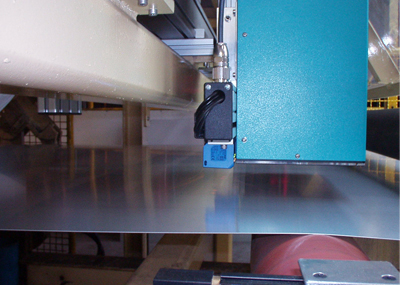

ERX145 Spectrophotometer: Used in the lab to measure standards and mounted on a traversing beam on the production line to measure color across the entire width of the coil and identify color variances early and reduce wasted product.

-

GlossFlash 6060 Inline Gloss Meter: Mounted alongside the ERX145 on the line to verify gloss values remain consistent with customer specifications throughout production.

-

ESWin Closed Loop Color Control Software: Easily control measurement devices and monitor color and gloss throughout production to keep color in tolerance and identify areas for improvement.

Featured Resources

Learn how an X-Rite inline color control solution helps coil coaters monitor color and consistency in real time to minimize waste.

Coil coating allows companies to paint metal in real time, during production, to achieve a uniform coating with consistent color and gloss quality. Learn more!

Join X-Rite in this free webinar and learn how X-Rite’s inline solutions for coil coating make it easy to monitor color throughout production so operators can make fast changes if color starts to shift.