Value Stream Mapping: What Is It?

You’ve no doubt heard the buzz around lean manufacturing and the benefits that “going lean” can accrue to your business. But where to start? Value Stream Mapping (VSM) is a lean management method for analyzing your current state and designing an improved future state.

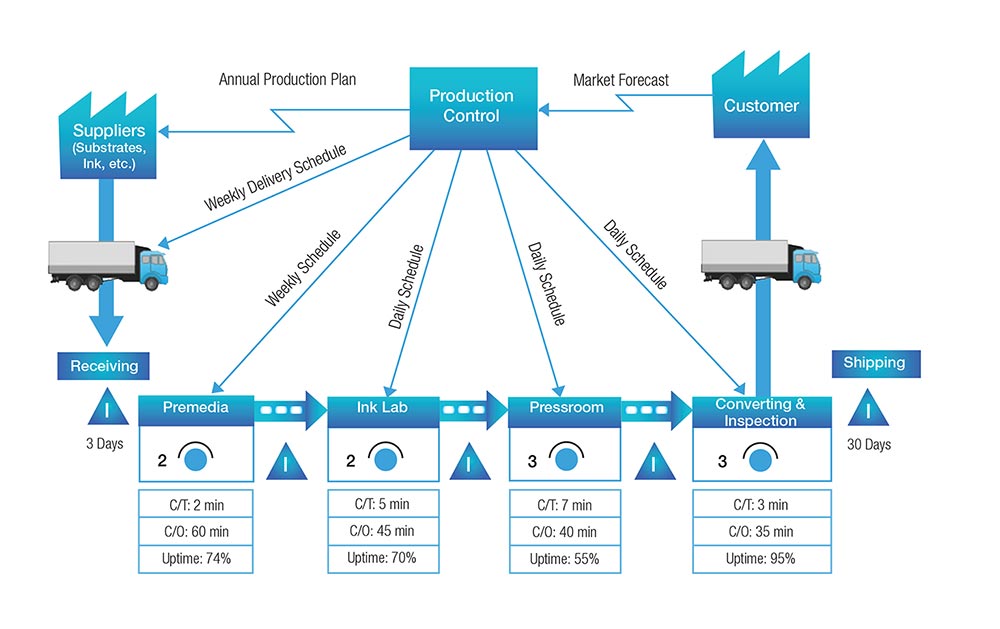

Value Stream Mapping (VSM) is used to visually represent all of the process steps that are required to complete a product or service. It is a representation of the flow of materials and data from supplier to customer through your organization. Using this tool, you can see at a glance where the sources of waste and delays are in your workflow, including constraints, excessive inventory and other obstacles or disconnects that may be affecting your productivity and throughput – and as a result, your profitability. It’s a great starting point for going lean and X‑Rite experts are here to help.

Key Advantages of implementing Value Stream Mapping at your Facility:

- Helps you to identify potential opportunities for improvement in prioritized manner, and provides an understanding of the process before change occurs.

- Enables a complete evaluation, with the ability to see and understand the entire process and set a strategy for improvement rather than trying to optimize on a piecemeal basis.

- Corrects root cause problems rather than simply addressing symptoms.

How it works

The X-Rite Value Stream Mapping process focuses on your color workflow. After all, accurate color is at the very heart of your business. A myriad of problems flow out of color issues, including waste, rework and unhappy customers.

Who is Involved

- X-Rite Value Stream Mapping Facilitator

- Subject Matter Experts as required

- Converter Quality Manager

- Converter Production Manager

- Converter Leadership Team

Preparation

In order to prepare for a successful Value Stream Mapping event, X-Rite will work together with your assigned team to agree upon a problem statement, event goals, key deliverables, and who the most effective team members are, including who owns the process, who is its sponsor in your organization, the active participants and any necessary supporting resources.

We will also identify any pre-work needed, as well as typical resources require to sustain improvements over time and ensure an environment of continuous improvement. In this way, you will have a full understanding of the commitment required on the part of your team, the benefits you can expect to see, and ensure that the necessary top-down support required for success exists within the organization.

The Deliverables

- 3 Day on-site session led by an X-Rite Senior Facilitator for Value Stream Mapping.

- Report detailing the ndings and recommendations.

- Detailed diagram outlining the Current to Future State transition.

- ROI – Return on Investment that can be expected by implementing the VSM results.

Benefits of Value Stream Mapping

- Improvements to Production – Defined by priority of biggest impact to your business, and with full ROI.

- Waste Reduction – Uncover and list all waste within the current workflow and means of reducing that waste.

- Timeline Improvement – List all areas where processing and lead-time can be improved and by how much.

- Overall Quality Improvement – Define all output from the workflow that can realize quality improvements through implementation of superior workflow or equipment, and tie each to profitability.

Achieving Operational Excellence in a Complex Packaging Supply Chain

In a dynamic and highly competitive environment, packaging converters are under increasing pressure to contain costs while maintaining the highest standards in color quality and consistency. In addition, clients are looking for packaging to be produced on a wider array of substrates and using a variety of printing technologies. This creates a complex color management environment that can challenge even the most exceptional converting operation. With solutions from the PantoneLIVE ecosystem, converters can leverage pure spectral values for spot colors throughout the production process to ensure accurate and repeatable color regardless of substrate, printing technology or ink types used. By adding ColorCert Suite to the configuration, converters can manage print operations to an even higher standard.

PantoneLIVE libraries cover more than 80% of packaging applications

PantoneLIVE now has a larger number of libraries available covering multiple print processes, packaging structures, and packaging types.

Flexibles

Flexo, Solvent-based ink- Reverse printed on clear film laminated to clear film

- Reverse printed on clear film over white ink

- Reverse printed on clear film laminated to printed on white film

- Reverse printed on clear film

- Printed on white film

- Printed on white film with heavy ink coverage

- Printed on coated paper

- Reverse printed on clear film laminated to clear film

- Reverse printed on clear film laminated to white film

- Printed on white film

Cartons

Offset, Conventional Ink- Printed on recycled board with gloss neutral coating

- Printed on virgin board with gloss neutral coating

- Printed on recycled board with gloss neutral coating

- Printed on virgin board with gloss neutral coating

- Printed on virgin board with gloss neutral coating

- Printed on brown kraft

- Printed on white kraft

- Printed on white recycle kraft

Labels

Flexo, UV Ink- Flexo UV on coated paper with gloss coating

- Flexo UV on white film

- Offset on coated paper with gloss neutral coating

- Offset UV on coated paper with gloss neutral coating

PantoneLIVE Solutions & Services

- Brand Owner Color Libraries

- Brand Owner Portal

- Color Audits

- ColorCert® Suite

- Color Matching & Harmonizaton

- Color Standards Creation

- Color Rationalization & PANTONE Mapping

- PantoneLIVE ColorBook & Viewer

- Color Audits

- ColorCert Suite

- Color iQC Print

- Color Standards Creation

- Esko Editor & FlexProof/E

- GMG ColorProof

- PantoneLIVE ColorBook & Viewer

- ColorCert Suite

- Color iQC Print

- Ink Formulation Software (IFS)

- Color Audits

- ColorCert Suite

- Color iQC Print Software

- ColorMetrix ProofPass

- Color Rationalization & PANTONE Mapping

- Color Standards Creation

- Ink Formulation Software (IFS)

- MeasureColor PressView

- PANTONE Certified Printer Program

- PantoneLIVE ColorBook & Viewer

Achieving Color Perfection

For more information about how PantoneLIVE solutions can help you better manage business challenges, such as ever-expanding ink inventories and reuse of leftover inks, visit www.pantone.com/live_harmonization_WP to download our free, informational paper, Managing Today’s Brand Equity Challenges.

Are you looking for a roadmap and action plan to help you improve your overall process effciency? Our experts are ready to help. Contact us by filling out the form.

PANTONE®, PantoneLIVE and other Pantone trademarks are the property of Pantone LLC. All other trademarks or registered trademarks are the property of their respective owners. Pantone is a wholly owned subsidiary of X-Rite, Incorporated. Licensed under Sun Chemical Corporation. Sun Chemical’s patented technology enables the communication of a consistent, digital description of the desired appearance of a product. – [U.S. Patent Nos. 7,034,960; 7,202,976; 7,268,918; 7,417,764 and their foreign equivalents]. © Pantone LLC, 2018. All rights reserved.