Learn how the right color solutions can help masterbatchers quickly achieve the best initial color matches to meet customer specifications and keep up with new color trends.

Learn how an X-Rite closed loop solution that includes a scanning system and integrated third party software offers commercial printers an affordable way to automate press process control.

Learn how colorists can utilize digital tools to help expedite the color approval process, speeding time to market and reducing their global footprint.

Learn how the ColorXRA Lab and ESWin software can help safety apparel manufacturers ensure fluorescent colors are within DIN, ISO, and ANSI tolerance to ensure wearer safety.

Assembled goods can be comprised of many parts and materials. Evaluating color in a custom fit-and-finish room under controlled lighting can ensure all parts match after assembly.

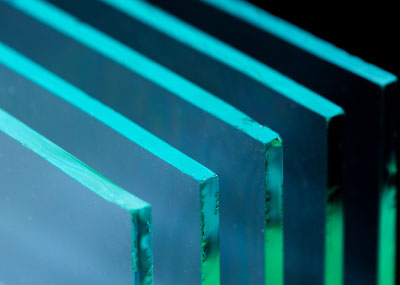

Learn how the ColorXRA G3 along with ESWin software can help glass coaters measure non-scattering glass panes, coatings, and insulation to verify consistent color.

Learn how the MA-5 QC multi-angle spectrophotometer and EFX QC software control color and appearance on bus and train special effect coatings and track data for process improvement.

Learn how X-Rite's Cup and Cylinder Fixture and an eXact Advanced or Ci64 spectrophotometer measure cylindrical-shaped samples at the correct height and angle.

Learn how the right color solutions can help textile dye houses quickly achieve the best initial color matches to meet customer specifications and keep up with new color trends.

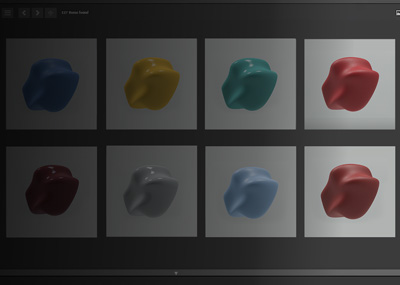

Learn how the X-Rite MetaVue VS3200 non-contact spectrophotometer and Color iQC software can accurately measure color on tiny, curved, molded, and odd-shaped plastic pieces.

Learn how the MA-5 QC multi-angle spectrophotometer, together with EFX QC software, improves color evaluation accuracy and validates whether parts are within specifications.

Learn how the MA-5 QC multi-angle spectrophotometer works with EFX QC software to improve color evaluation accuracy and track data for process improvement on assembled automotive parts.

As customers specify unique substrates and ink effects, ink manufacturers are struggling with additional challenges when managing the ink room.

Learn how hanging luminaires over a visual evaluation table can provide standardized lighting to evaluate textile color palettes, fabric rolls, multiple garments, and cut and sew pieces.

Learn how Industrial Designers can digitize complex materials and finishes to visualize photo-realistic color and appearance choices during the design phase for fast and early decision making.

Learn how Industrial Designers can digitize translucent or transparent plastics to visualize photo-realistic color and appearance choices during the design phase for fast and early decision making.

Learn how a digital color solution enables Life Science Manufacturers to produce consistent color and electronically track compliance for liquids, gels, powders, capsules, and more.

Learn how a digital color solution from X-Rite enables Life Science Brands to ensure the color on packaging color matches the product inside and track color compliance between suppliers.

Learn how a digital color solution from X-Rite enables printers to produce consistent color for transparent, translucent, and metallic packaging and electronically track compliance.

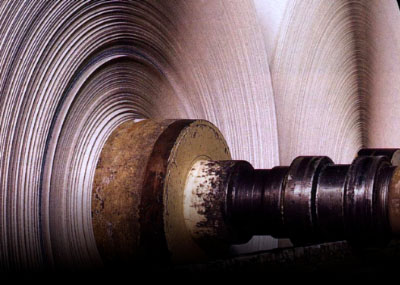

Learn how an X-Rite inline color control solution helps carpet manufacturers measure consistent color quality from left to right and beginning to end of each roll throughout production.

Learn how an X-Rite inline color control solution helps textile manufacturers measure the color of wet and dry denim yarn during and after the dye process.

Learn how the MA-5 QC multi-angle spectrophotometer and EFX QC software improve the accuracy of color evaluation and track data for process improvement on automotive paint.

Learn how X-Rite’s digital color measurement solution enables orange juice manufacturers to measure the color of juice and earn USDA approval for superior quality.

An X-Rite inline solution can help paper mills evaluate color quality and make real time adjustments throughout production to keep color and brightness harmony.

Learn how the X-Rite Payment Card Holder along with an eXact or Ci64 spectrophotometer can help printers monitor color and appearance on payment and loyalty cards.

Learn how X-Rite's inline solutions monitor and control the color of plastic film and sheets throughout production so corrections can be made early before the run is impacted.

Learn how having the right digital color solutions enables packaging printers to understand brand color requirements and efficiently formulate, produce, and control packaging color.

Learn how an X-Rite inline color control solution helps coil coaters monitor color and consistency in real time to minimize waste.

Learn how X-Rite digital color solutions enable manufacturers to communicate with Life Science brands and control the color of pharmaceutical products during formulation and production.

Learn how masterbatchers can use the PANTORA desktop app to create physically accurate virtual representations instead of fabricating expensive prototypes for reviews and approvals.

In the race to increase solar panel efficiency, X-Rite solutions can help capture precise color measurements on solar panels to quantify the capacity of energy production.

Learn how manufacturers can digitize coatings to visualize photo-realistic color and appearance choices during the design phase for fast and early decision making.

Learn how PANTORA and the MetaVue VS3200 non-contact benchtop helps brands and designers visualize the color and appearance of fine texture fabrics without creating expensive prototypes.

Learn how X-Rite’s color measurement solutions ensure the color of windows and doors match throughout the home or building and retain color integrity over time.

Learn how apparel, footwear, and soft good brands can connect the design-to-manufacturing workflow with spectral data and take a pivotal step toward sustainable manufacturing.

Learn how to streamline automotive product design and enhance quality control through accurate virtual material representation and digital prototyping.

X-Rite's innovative solution for paint color matching empowers manufacturers and retailers to craft custom colors, stand out from the crowd, and transform their businesses.

Still using fluorescent bulbs in your light booth? Learn how using X-Rite's Judge LED for color evaluation facilitates a seamless transition to LED for accurate and efficient color evaluation across the supply chain.

Learn how the MetaVue VS3200 non-contact benchtop spectrophotometer utilizes touch-free technology to safely deliver quicker, simpler, and more precise color evaluations for cosmetics.

Discover how the MetaVue VS3200 non-contact benchtop spectrophotometer overcomes inconsistencies in grit, texture, and color to deliver precise color evaluations of spice samples.

Learn how plastic manufacturers can digitize physical samples to create photo-realistic digital material libraries for their customers to make quick and accurate material decisions.

Learn how to use a color measurement device and software to enhance color precision in plastic molding, ensuring consistent, high-quality results, reduced waste, and enhanced customer satisfaction