How Plastic Manufacturers Can Create a Digital Material Library

Plastic manufacturers often struggle to set clear expectations with brands and designers for how a new plastic color will look on a final product. Creating a virtual rendering is a cost-effective and sustainable way to perform meaningful reviews and get stakeholder feedback before production even begins.

Challenges

When presenting new color choices to their customers, plastic manufacturers must bridge the gap between design expectations and the manufacturing process.

- Color and appearance attributes can change based on surface shape and viewing conditions

- Prototypes are expensive to produce and require long approval cycles

- Creating and shipping prototypes restricts manufacturers on the number of color samples they can present

- Assembled parts must match regardless of material type and assembled geometry

- Physical prototypes do not always match achievable production color, leading to false expectations

- Identifying a color issue after production wastes time and materials

Solution

Although measuring a plastic sample with a spectrophotometer delivers precise color values, the numbers don’t tell the whole story. PANTORA offers advanced functionality to fully visualize color and appearance in real-life image quality based on the shape, surface type, and assembly angle of the parts.

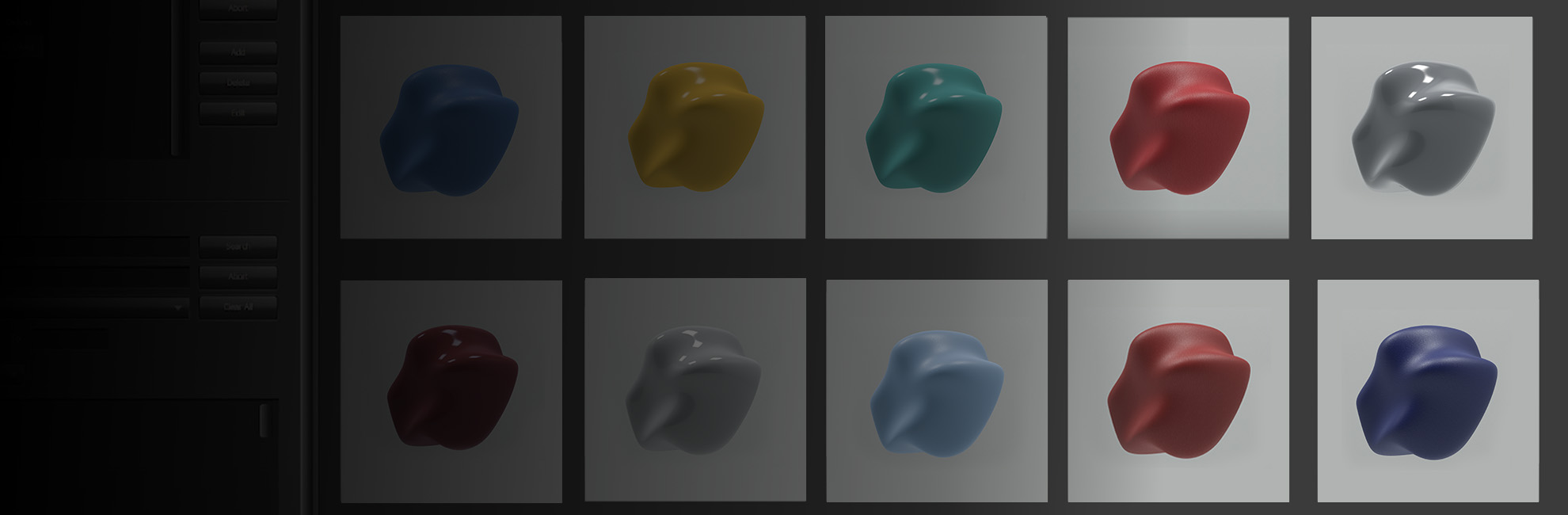

Instead of fabricating prototypes to demonstrate how color will appear on the final product, plastic manufacturers can use the PANTORA desktop application to create a physically-accurate virtual representation. This enables designers, engineers, and brand stakeholders to visualize a plastic material from multiple angles and simulate how color and appearance characteristics will react under different lighting conditions.

Powered by X-Rite’s AxF format, this representation can be visualized within PANTORA as well as imported into third-party visualization and simulation tools for use in a range of industries, including automotive, consumer electronics, durable and home goods, cosmetics, etc.

Results

Creating a virtual rendering that goes beyond color to capture full material appearance is a fast, easy, and economical way to gain stakeholder buy-in.

- Sets realistic expectations by accurately characterizing color and plastic appearance attributes like translucency

- Enables plastic manufacturers to economically present a wide range of color options

- Generates fast approval without the time and material waste of prototypes

- Identifies color issues before production begins by applying to a virtual replica that includes different surfaces, curves, and edges

- Establishes a spectral and texture data audit trail for formulation and production QC to ensure consistency throughout the process

- Ensures fast and easy material specifications and enables reuse though a digital repository

How It Works

- The plastics manufacturer uses a spectrophotometer to measure the target color.

- A sphere benchtop spectrophotometer such as the Ci7860 or Ci7800 can capture both color and plastic attributes like translucency.

- A multi-angle handheld spectrophotometer like the MA-T12 can fully characterize color and appearance of a plastic sample.

- PANTORA locates, acquires, and imports digital materials as AxF files, applies the material to arbitrary geometry, and renders it in real-time in a virtual scene for an immersive digital material evaluation experience.

- The plastics manufacturer sends the digital rendering to designers, brands, and all stakeholders for review and approval through a third-party rendering solution or PLM system.

- These digital materials can be stored, managed, viewed, and edited in AxF from a centralized location for future recipes and to create marketing materials.

Featured Products

X-Rite's PANTORA Appearance software is a tool for managing, editing, and visualizing digital material appearances for accurate color and texture reproduction across various industries.

Industry-leading benchtop sphere spectrophotometers that offer both reflectance and transmission measurements to control critical color on opaque and non-opaque materials with tight tolerances.

A multi-angle spectrophotometer to establish the strictest standards for extreme effect finishes. With an RGB color camera and 12 angles of measurement, the MA-T12 can characterize special effect materials and ensure consistency across adjacent parts in distributed supply chains.

Quality assurance software that verifies and optimizes performance of all connected color measurement devices to reduce variance among instruments and measurements.

Third Party Rendering Software

Renderings made using PANTORA can be viewed by brands and designers using AxF-enabled rendering software solutions. Visit our website for the most current list of vendors: https://www.xrite.com/axf.

Achieve Color Success

PANTORA can help plastic manufacturers visualize the color and appearance of plastic samples and create a virtual library to present more options at the design phase and speed approvals. Learn more at www.xrite.com/pantora.